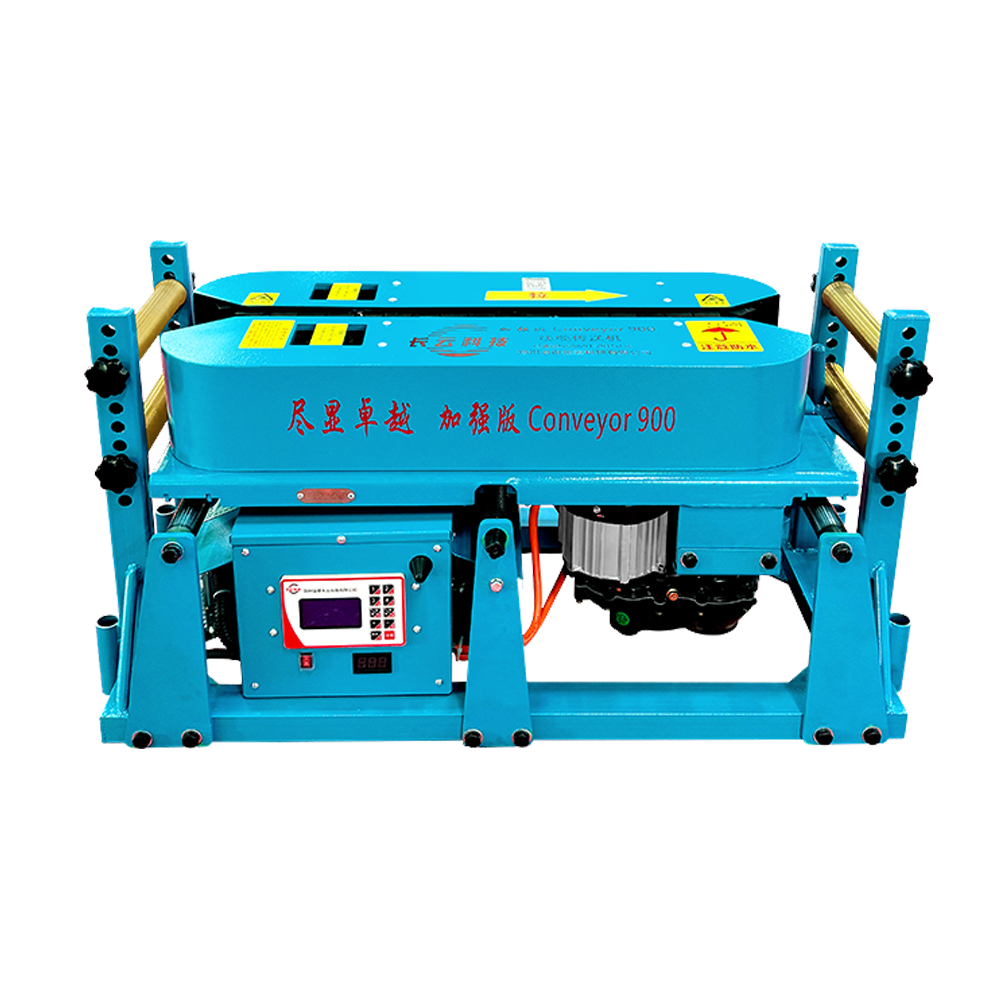

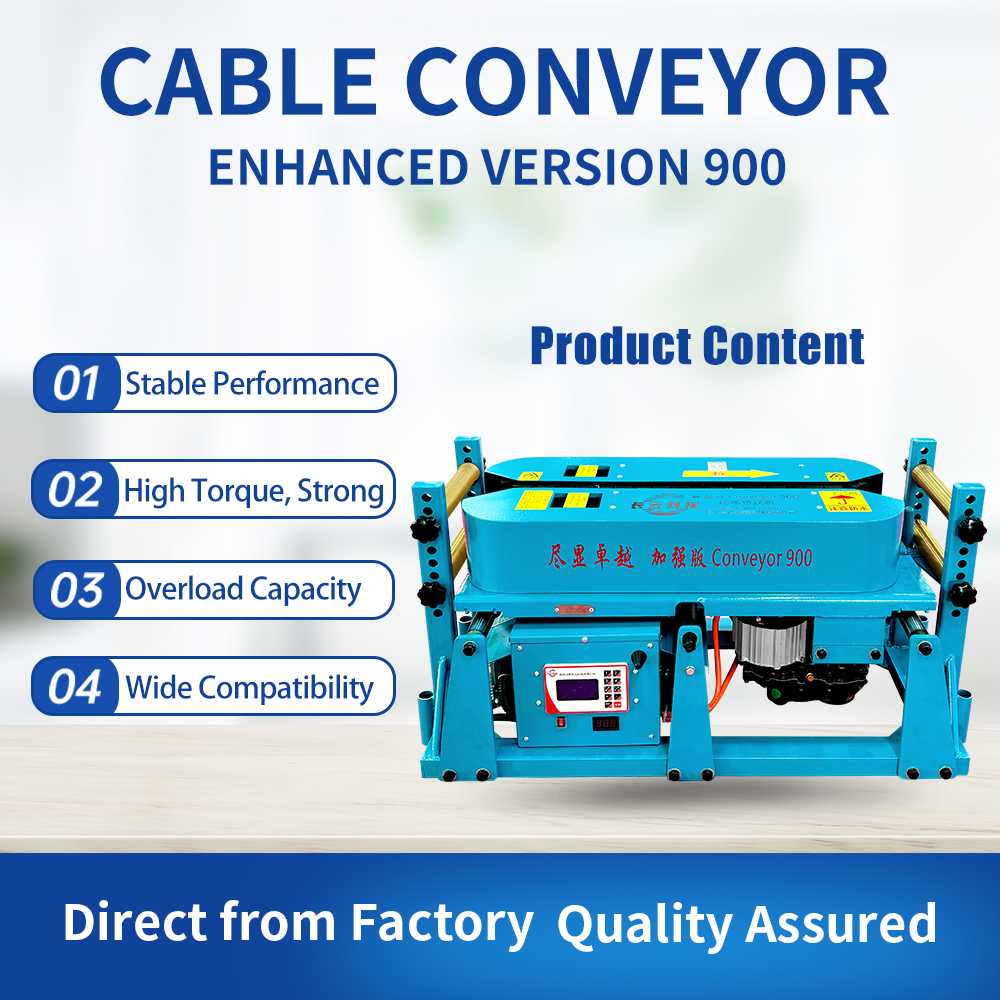

Product Content:

Stable Performance,

High Torque, Strong

Overload Capacity

Wide Compatibility

Product Parameters:

Power Supply: AC380V (Standard) / AC220V (Customizable)

Speed Regulation: 4 Gears + Stepless Speed Regulation

Control Method: Control Panel + Remote Control

Power: 1800W x 2

Conveying Speed: 4~26 m/min

Enhanced Version Conveyor 900 (Showcasing Excellence)

Optimal Speed: 10-16 m/min (2nd, 3rd Gear)

Maximum Pulling Force: 8000 N

Cable Diameter Range: 2~24 cm

Overall Dimensions: 106.4 x 57 x 53 cm

Net Weight: 214 kg

Product Description:

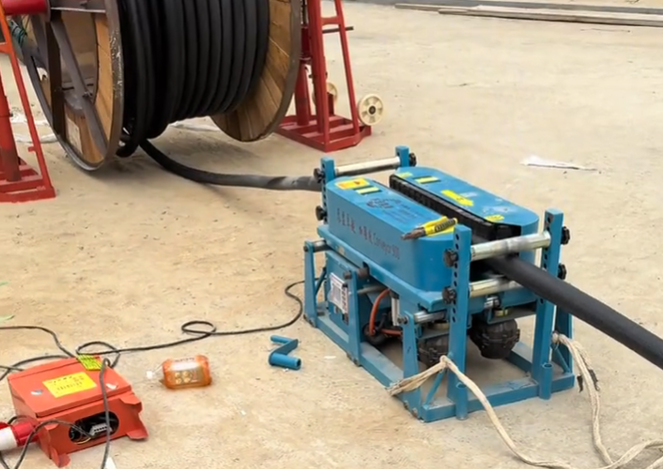

This machine features a compact and rational structure, excellent performance, smooth operation, low noise, high conveying speed, and easy maintenance. It is suitable for long-distance cable installation, such as cable tray cables, cables in subway tunnels, instrumentation cables, and electrical control line installation.

This machine can operate in both "forward" and "reverse" directions, with four main speed gears. Additionally, stepless speed regulation can be achieved using the "+" and "-" controls. The machine and remote control can be grouped by frequency matching, allowing them to operate independently without mutual interference. It also supports multi-unit synchronized control for operation from distant locations.

Product Features:

Compact Structure, Rational Design

Stable Operation, Excellent Performance

Dual Pure Copper Core, Durable and Reliable

Bidirectional Operation, Four Adjustable Gears

Multi-unit Synchronized Control, Remote Command

Product Packaging & Shipping

We ensure your machinery arrives in perfect condition, ready for immediate use, through robust packaging and flexible shipping solutions.

1. Packaging Methods:

Standard Export Wooden Cases: Each machine is securely fixed within a custom-built crate, which is specifically designed to prevent damage from moisture, impact, and rough handling during long-distance transportation.

Comprehensive Internal Protection:

Machines are first wrapped in heavy-duty plastic film for moisture and dust protection.

They are then secured inside the cases using high-strength straps and foam padding to eliminate any movement.

All accessories, remote controls, and documentation are individually packaged and sealed within the main wooden case.

Clear External Marking: Cases are clearly labeled with:

Product Name & Model

Gross/Net Weight

Package Dimensions (L x W x H)

Handling Instructions (e.g., "Fragile," "This Side Up," "Keep Dry")

Your unique order number for easy identification.

2. Shipping Methods: (e.g., Deppon Logistics)

We offer various shipping options to best suit your timeline and budget:

Rail Transport: Railway transportation offers stable transit times and is unaffected by weather, providing reliable logistics support for your foreign trade orders.

Sea Freight (FCL/LCL): We tailor the most economical solutions for each buyer order.

Air Freight: To expedite urgent or small-volume orders, we coordinate with air carriers to ensure timely delivery.

After-Sales Service & Support

1. Warranty Policy

We provide a standard warranty period of 12 months commencing from the date of delivery.

The warranty covers all manufacturing defects and malfunctions under normal operating conditions.

During the warranty period, any product-related issues will be evaluated on a case-by-case basis, and necessary support and services will be provided.

2. Global Technical Support

Lifetime Free Consultation: We offer free, lifelong technical consultation via email, WhatsApp, and WeChat. Our engineers are readily available to answer any operational or technical inquiries you may have.

Remote Diagnostics: For specific issues, our technical team can provide remote guidance and troubleshooting through online video calls.

3. On-Site Service

For complex issues that cannot be resolved remotely, we can arrange for certified engineers to provide on-site service. This service includes:

Equipment installation, commissioning, and calibration.

On-site operation and maintenance training for your personnel.

Thorough inspection and repair.

Delivery Details:

Method: By sea or air freight.

Delivery: Within 3 days of payment receipt.

Packaging: Standard export wooden crates with waterproof lining and foam padding for fixation.

Tracking: Shipping documents & tracking number provided via email.

Company Information:

Zhengzhou Zhi Shi Changyun Technology Co., Ltd., established on June 30, 2014, is a comprehensive enterprise integrating R&D, manufacturing, and sales. Its business spans machinery manufacturing, communication equipment, and engineering machinery, with main products including cable conveying machines, Optical Cable Pulling Machines, and winch grinders, among other professional equipment. The company operates a modern production facility covering 6,000 square meters and employs over 150 technical professionals. It has obtained ISO9001 quality management system certification and nearly 100 patent grants. Its products are widely used in power engineering, communication networks, transportation infrastructure, and other fields, with a nationwide sales and service network. The company provides a year-round 24/7 telephone consultation service, and its technical team can respond to on-site issues within 48 hours. In 2023, it was recognized as a High-Tech Enterprise in Zhengzhou and has maintained the title of "Contract-abiding and Credit-worthy Enterprise" for five consecutive years (2020-2025).

Product Cases:

1.Enhanced 900 Cable conveyor for Residential Area Construction

During a cable renovation project in a residential area, the construction team utilized Changyun Technology's enhanced Conveyor 900 cable conveyor for low-voltage cable installation. Leveraging its robust conveying power and protective rubber wheel design, the equipment efficiently completed the 300-meter cable pulling through conduits, effectively preventing damage to the cable sheath. This resulted in a 50% improvement in construction efficiency and received high recognition from on-site personnel.

2.Efficient Cable Pulling with the Enhanced 900 Conveyor.

During the electrical installation at a newly developed construction site, there was a requirement to lay hundreds of meters of large-cross-section high-voltage cables. Traditional manual pulling methods proved inefficient and posed significant risks. The installation team introduced the "Enhanced 900 Cable Conveyor," whose powerful thrust and exceptional stability easily overcame the challenges of long-distance and complex conduit layouts. Through synchronized operation of multiple units, the cable was laid at a consistent speed and with smooth, damage-free performance. This approach boosted construction efficiency by over 300%, substantially saved labor and time costs, and provided a solid guarantee for the project's successful power-up.

Frequently Asked Questions:

Q1: After starting up, the crawler does not rotate or slips, failing to convey the cable properly. How should I troubleshoot this?

A:Incorrect Pressure Adjustment: Check and adjust the clamping pressure of the crawler on the cable. Insufficient pressure will lead to a lack of friction and cause slipping, while excessive pressure may damage the cable or cause motor overload. Precisely adjust the pressure according to the outer diameter of the cable being laid, referring to the calibration marks on the equipment or the recommended values in the manual.

Crawler Wear or Debris Clogging: After prolonged use, the crawler tread pattern can wear down, reducing friction. Please check the crawler for wear and replace it promptly if severely worn. Simultaneously, clean any oil, mud, or other debris that may have accumulated in the crawler grooves and on the drive wheel.

Power Source Issue: Confirm that the oil pressure and flow of the hydraulic power station (if hydraulically driven) meet the rated values, or verify that the electric motor (if electrically driven) is operating normally and the power supply voltage is stable.

Q2: When multiple 900 Enhanced Version Cable Conveyors operate together, how can synchronized operation be ensured to prevent cable pile-up or breakage?

A: Synchronized multi-machine operation is crucial for cable laying. The 900 Enhanced Version typically supports a centralized control system. Please ensure:

Correct Control Cable Connection: Use the dedicated interconnection control cable provided by the original manufacturer to securely connect all units to the central control box.

Activate Synchronization Function: Start the "Linkage" or "Synchronized" mode on the control box. This mode uniformly coordinates the start/stop and speed of all units, making them operate as a single system.

Setup and Fine-Tuning: Before synchronized operation, perform individual unit jog tests to ensure all units rotate in the same direction. During the initial operation phase, closely observe the cable condition between the machines. Use the speed fine-tuning function on the control box to make precise adjustments to any units running slightly faster or slower until perfect synchronization is achieved.

Q3: What are the key precautions for the daily use and maintenance of the equipment?

A: Proper maintenance significantly extends equipment life and ensures operational safety. Please pay attention to the following points:

Daily Cleaning and Lubrication: After each operation, be sure to clean dust and oil grime from the machine body and crawler. Regularly apply the designated grease or lubricating oil to moving parts such as transmission chains and bearings to keep them operating smoothly.

Crawler Inspection and Maintenance: When not in operation, release the crawler pressure appropriately to avoid keeping the crawler under constant tension, which accelerates aging. Regularly check the crawler tension and adjust it to the optimal working state.

Storage and Environment: The equipment should be stored in a dry, ventilated indoor environment, protected from rain and direct sunlight. Before long-term storage, perform a comprehensive cleaning and maintenance of the equipment, and apply anti-rust oil to exposed metal parts.

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

RELATED

Ce site Web utilise des cookies pour vous garantir la meilleure expérience sur notre site Web.